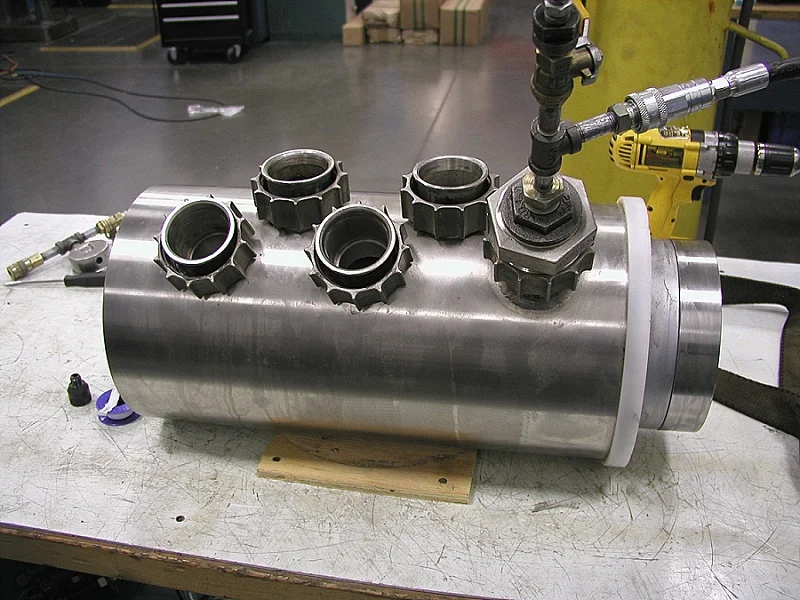

Columbia Energy inspected, repaired, and hydro tested a spare rotary union for the Vacuum Mobile Arm Retrieval System (MARS-V) for Washington River Protection Solutions (WRPS).

Repair of the rotary union required the removal of 10 ports on the union assembly with the shaft removed from the housing prior to cutting or welding. New Safety Significant Chem-Joint connectors were welded in accordance with ASME B31.3 and RPP-CALC-42345, Appendix 48. Welds were inspected by Columbia Energy’s AWS QC-1 certified weld inspector.

The repair process and procedures were documented in a traveler that described the step-wise performance of the repair.

Three pressure tests were performed: 2 hydrostatic tests and 1 pneumatic test. The hydrostatic testing involved examining the housing, flange, connections, adjacent ports, and open leak ports, followed by a pressure leak test report. The pneumatic test involved applying test pressure to selected gas port.

At the conclusion of repair and testing, Columbia Energy submitted the traveler and testing documentation to WRPS prior to delivering the repaired Rotary Union.

Specifications

- B31.3 Piping

- Safety Significant Chem-Joint connections

- Hydrostatic pressure tested to 637.5 psig +20/-0

Stakeholders

- U.S. Department of Energy (DOE)

- Office of River Protection (ORP)

- Rotary Systems manufacturer

- River Bend

Services

- ASME B31.3 Hydrostatic Testing

- Pneumatic Static Pressure Testing

- NQA-1 Oversight

- Fabrication

- Documentation

- Packaging

- Delivery