Columbia Energy has a staff of Instrumentation and Controls (I&C) professionals who have the expertise to design, build, install, and test control systems. In addition to providing I&C services for new applications, we can upgrade existing relay-based and PLC based-control systems.

Equipment and Facilities include:

- Process Control Laboratory for designing and testing of control systems

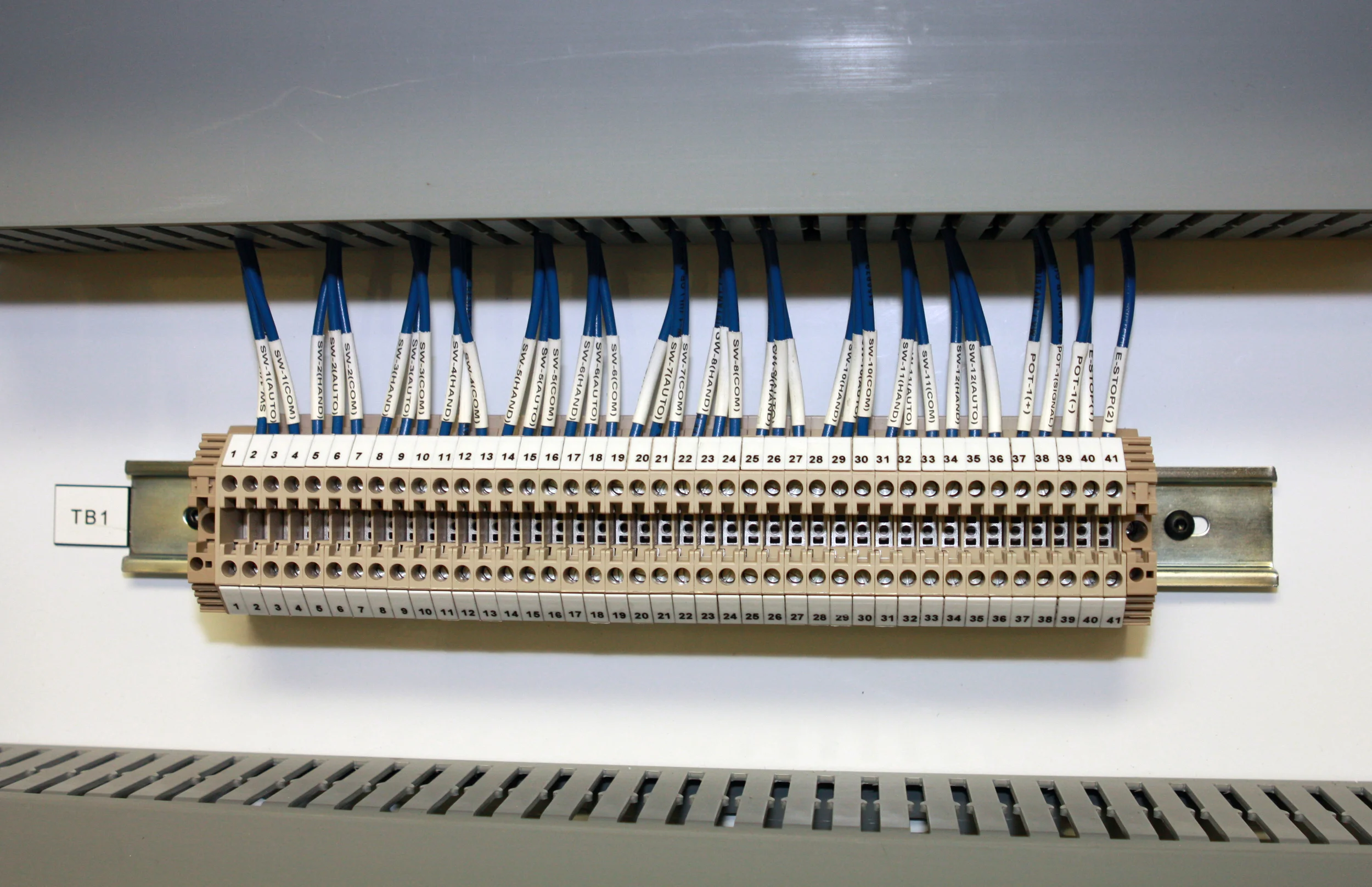

- UL508A and UL698A Panel Fabrication Shop

- Instrumentation Calibration Laboratory

- Portable equipment for field testing

- Operator consoles

Columbia Energy’s Process Control Laboratory has field emulation equipment to assist in designing, fully testing, and integrating control systems before they leave the laboratory.

I&C Services INCLUDE:

- Electrical / I&C design drawings, including:

- General arrangemen

- Wiring diagrams

- P&IDs

- One-lines

- Bill of Materials

- Elementary drawing

- Complete component selection for building panels

- PLC and HMI Software development and testing

- Control panel design and assembly

- Process control instrumentation

- Full mock up testing of projects

- On-site startup and commissioning

- Field troubleshooting

- Complete DCS architecture and design

Columbia Energy remains technology neutral when selecting software and hardware. We select software based on the best fit for the customer or customer preference. We have direct hands on experience with software development tools, such as:

- ABB CADEWS Configuration

- ABB Harmony family

- ABB Industrial IT

- ABB PC View/LAN90

- ABB Process Portal A&B

- ABB Pwr & Gnd for DC

- ABB Operator Interface Units

- ABB OIS series

- ABB Mngt Command Series

- ABB System 800xA Eng

- ABB WinTools Config

- Citect

- Concept XL

- Directsoft

- Devicenet

- Intellution

- In Touch HMI

- LabVIEW

- Modsoft

- Net Arrays

- Opto 22

- PC Device Lib

- RS Logix family

- TIsoft

- Visual Basic

- Visual C++

- Wonderware